Excessive motion at the end of a move can cause damage to the load or surrounding structures and can increase the time required to position the load in the correct spot

How to Eliminate Sway?

METHODS

One can eliminate end-of-move sway in several ways, however all except one have proven to be expensive and ineffective.

WRONG WAYS

Mechanical Sway Prevention. This is the worst way to handle sway. This method requires building a structure that can move a load horizontally in lock step with the trolley. This new structure must be able to absorb massive torque to accelerate and decelerate the load without allowing sway. This applies bending moments to whatever structure is used, every time the load is moved. The longer the hang, the greater the bending moment. Repetitive moves eventually fatigue the structure, causing failure. In addition, the extra weight needed for the sway preventers requires extra support from the crane structure and consumes additional power. Mechanical methods include simple differential reeving, where the cables are not vertical; long arms extending horizontally from the fulcrum and extra cables for sway mitigation; and solid vertical beams instead of or in addition to cables. All these methods share the same defects of adding torque to a naturally torque-free system, consuming extra energy, and causing long-term maintenance headaches.

Final Correction. In this method, the fulcrum (trolley or boom tip) is moved to the destination without regard to the effects of sway. At the end, a sensor determines the amount of residual sway and a control algorithm adjusts the fulcrum to remove it. This is not a good method because the sway can be very large at the end, requiring large and uncomfortable corrections and much time to reduce sway to acceptable levels.

THE RIGHT WAY

Predictive Sway Prevention (Open Loop). SmartCrane uses this patented method to correct the acceleration of the pivot so as to remove the sway added to the load every time the fulcrum is moved. Because the sway is a periodic function, that correction can only be made one-half pendulum period later. This is often called "bang-bang" method because every motion of the fulcrum is made of of two parts separated by a certain time period depending on hoist action. This method works best when the pendulum is a simple one (no differential reeving or other mechanical sway mitigation) because the sway period can be estimated accurately. This method only suffers from one defect: it cannot correct for sway introduced by other external factors such as non-vertical lift and wind.

Combination Predictive and Feedback (Closed Loop). This method uses the good features of the predictive method to prevent all sway induced by motion, correcting any externally-induced sway based on sensor readings. These corrections require only minimal movements (if any) at the end of the move. This combined approach provides a smooth, comfortable, and safe ride for both load and operator. SmartCrane supplies both Open Loop and Combined Open- and Closed-Loop systems.

THE PHYSICS OF SWAY CONTROL

The Physics. A weight suspended on a long string or cable acts very much like a pure pendulum. In a frictionless environment, once the weight is offset from the vertical, it will swing back to a point just as far on the other side and keep doing that forever. Try it with a heavy weight and a string from a balcony.

The length of time it takes for the weight to get back to the same position on every cycle is called the pendulum period. The period is dependent only on the length of the pendulum and has nothing to do with how much weight is attached. (In the real world, there is always some air friction on the string and the weight, so the heavier the weight, the more it acts like a frictionless pendulum.)

Sway Begins Immediately. When the fulcrum accelerates horizontally, the angle of the rope or cable changes. This transfers some of the force of gravity on the pendulum from vertical to horizontal (a sine function). This horizontal force starts the load moving. Unless special care is taken, that horizontal load motion will turn into a harmonic motion back and forth, what we call “sway.” This sway will persist or even increase as more acceleration is applied. When the fulcrum stops, there will usually be residual sway, the degree of which is determined by the acceleration pattern. Unless there is lots of friction or something else (such as angled cables) to stop it, the will keep swaying for a long time. With well timed fulcrum movements, it is possible to reduce this residual sway but it takes time.

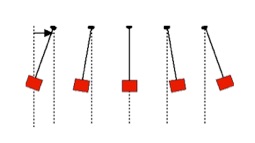

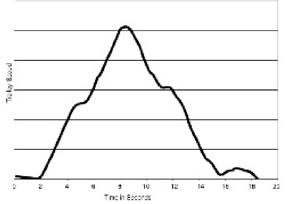

If the accelerations of the fulcrum are controlled properly during the move, then sway can be eliminated when the fulcrum is at steady state (either moving at constant velocity or stopped). If this is done precisely, then you will see the weight hanging straight down below the fulcrum. Stopping is simply the reverse of this process (see a typical speed profile from a real crane below).

Watch the animated picture here showing what happens when a load is moved with Anti-Sway.

©Copyright 2018 by SmartCrane, LLC - All rights reserved.